Failure Mode and Effects Analysis

"Anything That Can Go Wrong, Will Go Wrong" Murphy's General Law

What is FMEA?

Failure Mode and Effects Analysis (FMEA) is a systematic approach for identifying probable failures in a system, product, or process, evaluating their impacts, and figuring out how to minimize or prevent them. FMEA is a proactive method that seeks to foresee future issues and deal with them in advance of happening rather than responding to them after the fact. Reliability, safety, and quality control are frequently addressed in engineering design through the FMEA process.

In order to identify probable failure modes, their consequences, and their causes, a team of experts conducting a basic FMEA process thoroughly reviews a system, product, or process. On the basis of severity, the likelihood of occurrence, and detectability, the team then assigns a rating to each probable failure mode. The possible failure modes are ranked according to importance using the information provided. The team then creates and puts into effect measures to avoid or minimize the most critical failure scenarios.

FMEA fosters a proactive approach to problem-solving, which is one of its main advantages. Organizations may avoid or reduce difficulties by spotting them in advance and taking action, thereby saving time and money. Exploring "what-if" scenarios is encouraged by the qualitative process of FMEA, which may be used to find probable failure modes that would not be apparent by other methods.

FMEA's ultimate objective is to limit or completely eradicate the likelihood of crucial failures. Organizations may enhance the dependability, safety, and quality of their goods and services, which will boost client happiness and loyalty by taking a systematic approach to identifying and resolving possible issues.

History Facts

In order to assess probable failures and their impact on military equipment, the US military created FMEA in the 1940s. FMEA was used by the military to reduce the risk of equipment failure during operations and to guarantee that it was dependable.

The aerospace sector first used FMEA in the 1960s to assess possible risks and product failures, and it quickly became a crucial step in their design and production processes. FMEA was implemented by the automotive industry in the 1970s in order to assure the safety and dependability of their cars in light of the growing complexity of automotive systems.

In the 1980s, several sectors embraced FMEA as a reliable technique for spotting probable failures. During this time, the Society of Automotive Engineers (SAE) developed a standard approach for FMEA implementation that included best practices for applying FMEA across industries.

A new standard known as Design FMEA (DFMEA), which is used exclusively for examining the risks and potential failures connected with product design, was released in 2008. A development of the conventional FMEA method, DFMEA concentrates on locating and preventing any flaws during the design stage itself.

The AIAG-VDA FMEA Harmonization Project, which sought to unify several FMEA standards and guides across sectors, gave FMEA a facelift in 2019. By removing redundancy and streamlining the technique, this initiative attempted to improve the FMEA process' efficiency and effectiveness.

How to Сonduct FMEA

Figure 1 - AIAG-VDA FMEA process

The FMEA procedure is thoroughly described in the widely used AIAG-VDA FMEA Handbook. Here is a list of all the steps needed:

- Planning and Preparation. Establish ground rules and timetables, assemble the team, and specify the FMEA's goals and scope.

- Structure Analysis. Create a block diagram or process flow chart, define the system or process that is being studied, and then list its functions and needs.

- Function Analysis. Determine the possible failure modes for each function and their implications for the process or system.

- Failure Analysis. Determine the root causes of each failure mode and gauge the extent to which it has affected the process or system.

- Risk Analysis. Determine the present controls in place to prevent or detect failures by assessing the frequency and likelihood of each failure mode occurring.

- Optimization. Create recommendations for reducing the severity, occurrence, and increasing detection of high-risk failure types.

- Results Documentation. Document the FMEA's findings, including the suggested measures and the status of those actions' execution.

Each step is sequential, so the previous step creates output data that serves as input for the next step.

The AIAG-VDA FMEA Handbook also offers recommendations on how to rate severity, occurrence, and detection levels as well as define countermeasures for high-risk failure modes. To guarantee ongoing improvement of the system or process under analysis, the iterative FMEA approach should be often reviewed.

Read also: HIPAA Compliance in Software Development

FMEA Case: Order Fulfillment by Online Store

In this article,the FMEA process using the example of the order fulfillment process in an online store will be analyzed.

Define Scope and Objectives

First, the scope and purpose of the FMEA needs to be defined. This involves defining the product or process to be analyzed, the purpose of the analysis, and the team of experts who will conduct the analysis. It is important to note that the team should be truly cross-functional, i.e., with people with different knowledge of the process, product or service, and customer needs. That is, this process is not conducted by only one team member (e.g., a business analyst or project manager), but almost all stakeholders, both internal and external, should participate in it.

For the case study at hand, we first describe what exactly will be investigated, namely the process of receiving, selecting and packing, as well as delivering orders. The next section shows why this is done, for what purpose. It also identifies a cross-functional team that will conduct this analysis.

|

Scope |

Objectives |

Team members |

|

The Order Fulfillment process, which comprises the stages of receiving, selecting and packaging, and delivering orders, will be the subject of the FMEA study. |

1. Identify potential failure modes and associated risks in the Order Fulfillment process. 2. Prioritize failure modes based on their severity and occurrence, and develop appropriate corrective actions to reduce the risks. 3. Verify the effectiveness of corrective actions and establish ongoing monitoring and measurement to ensure sustained effectiveness. 4. Improve product quality, reduce customer complaints, and increase process efficiency. |

Operations Manager Production Manager Shipping Manager Quality Manager IT Manager Customer Service Representative |

Identify potential failures and effects

Next, all potential failure modes and their impact should be identified. This can be done by brainstorming, reviewing historical data, or using other tools such as fault tree analysis, for example.

|

Failure Mode |

Effect |

|

Incorrect item shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

|

Incorrect quantity shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

|

Delayed shipment |

Customer dissatisfaction, potential loss of revenue, potential damage to customer relationship |

|

Damaged product during shipping |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue, potential damage to customer relationship |

Evaluate Severity, Occurrence, and Detectability

Once the potential failures have been identified, it is necessary to assess the severity, occurrence, and detectability of each failure.

Severity is the seriousness of the effect of a failure mode on the customer or end user. Occurrence is the probability or frequency of the failure mode occurring. And detectability is the ability of current controls or systems to detect the failure mode before it reaches the customer or end user. The scores are quantified by the expert group identified in the first step.

|

Failure Mode |

Effect |

Severity Rating |

Occurrence Rating |

Detection Rating |

|

Incorrect item shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

8 |

4 |

9 |

|

Incorrect quantity shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

7 |

3 |

8 |

|

Delayed shipment |

Customer dissatisfaction, potential loss of revenue, potential damage to customer relationship |

6 |

5 |

7 |

|

Damaged product during shipping |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue, potential damage to customer relationship |

9 |

2 |

8 |

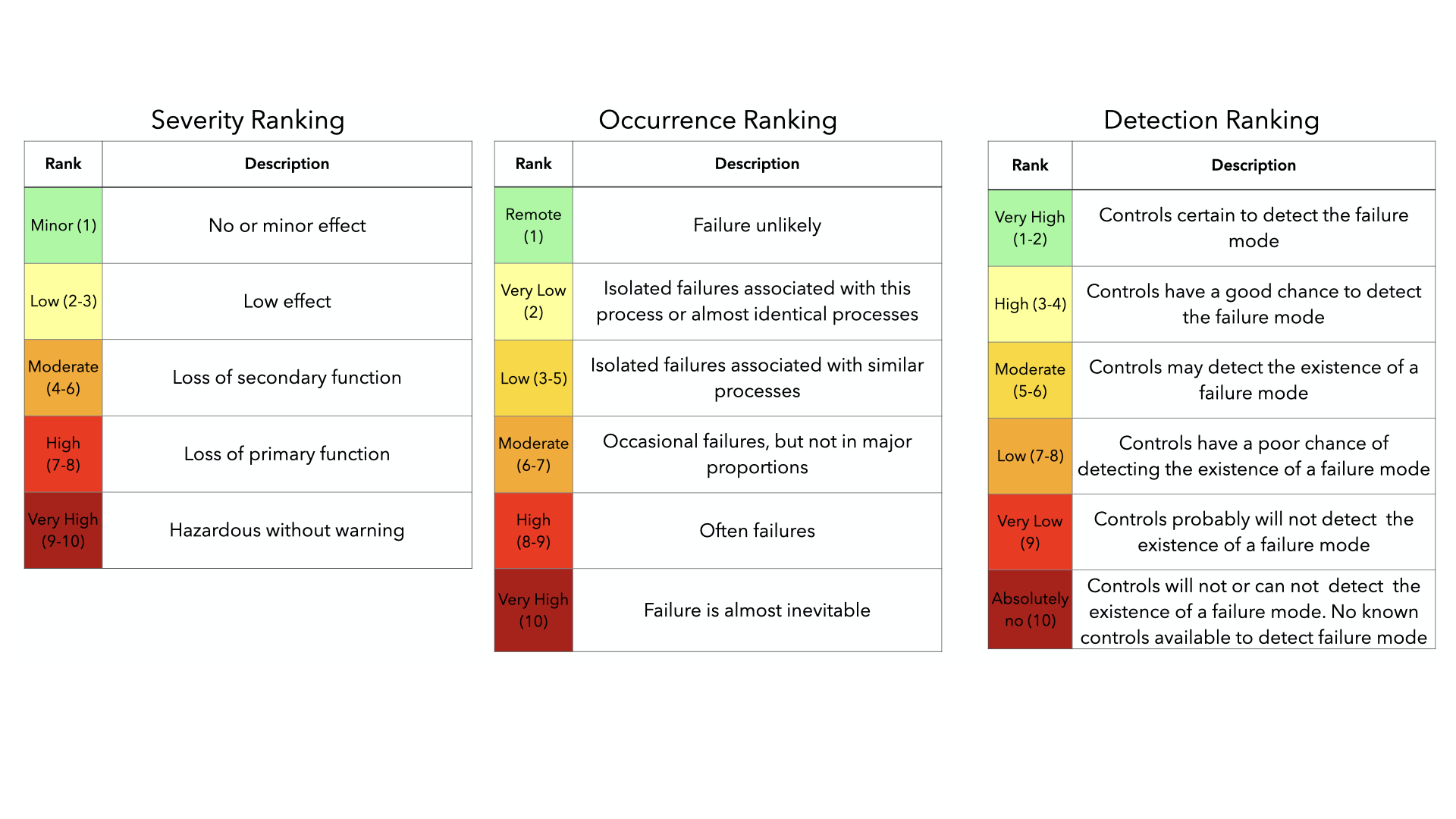

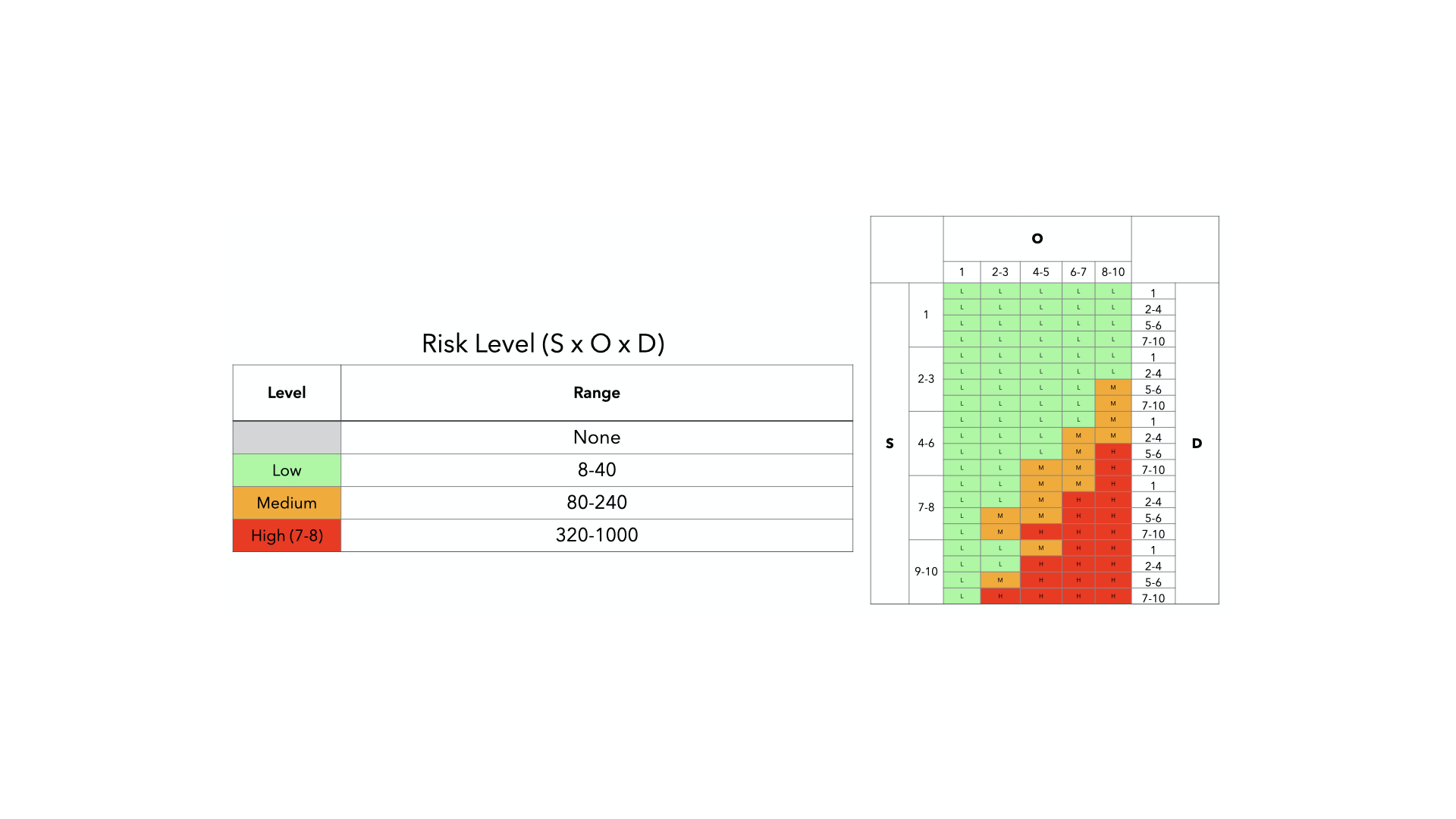

Scales for Evaluation

A set of scales is typically used to evaluate the severity, frequency of occurrence, and detectability of potential failures during an FMEA. These scales are used to assign numerical ratings to each failure mode, which allows for the calculation of a risk priority number (RPN).

Some of the scales used include:

- Severity. A scale from 1 to 10, where 1 is the least serious and 10 is the most serious. The severity rating is based on the potential impact of the failure mode on the client or end user.

- Occurrence. A scale from 1 to 10, where 1 is the least likely and 10 is the most likely. The frequency rating is based on the probability of the failure mode occurring.

- Detectability. A scale from 1 to 10, where 1 is the most detectable and 10 is the least detectable. The detectability score is based on the ease of detecting the failure mode before it causes a problem.

Some organizations modify these scales to suit their needs.

Figure 2 - Scales for Evaluation

Risk Calculation — Risk Priority Number (RPN)

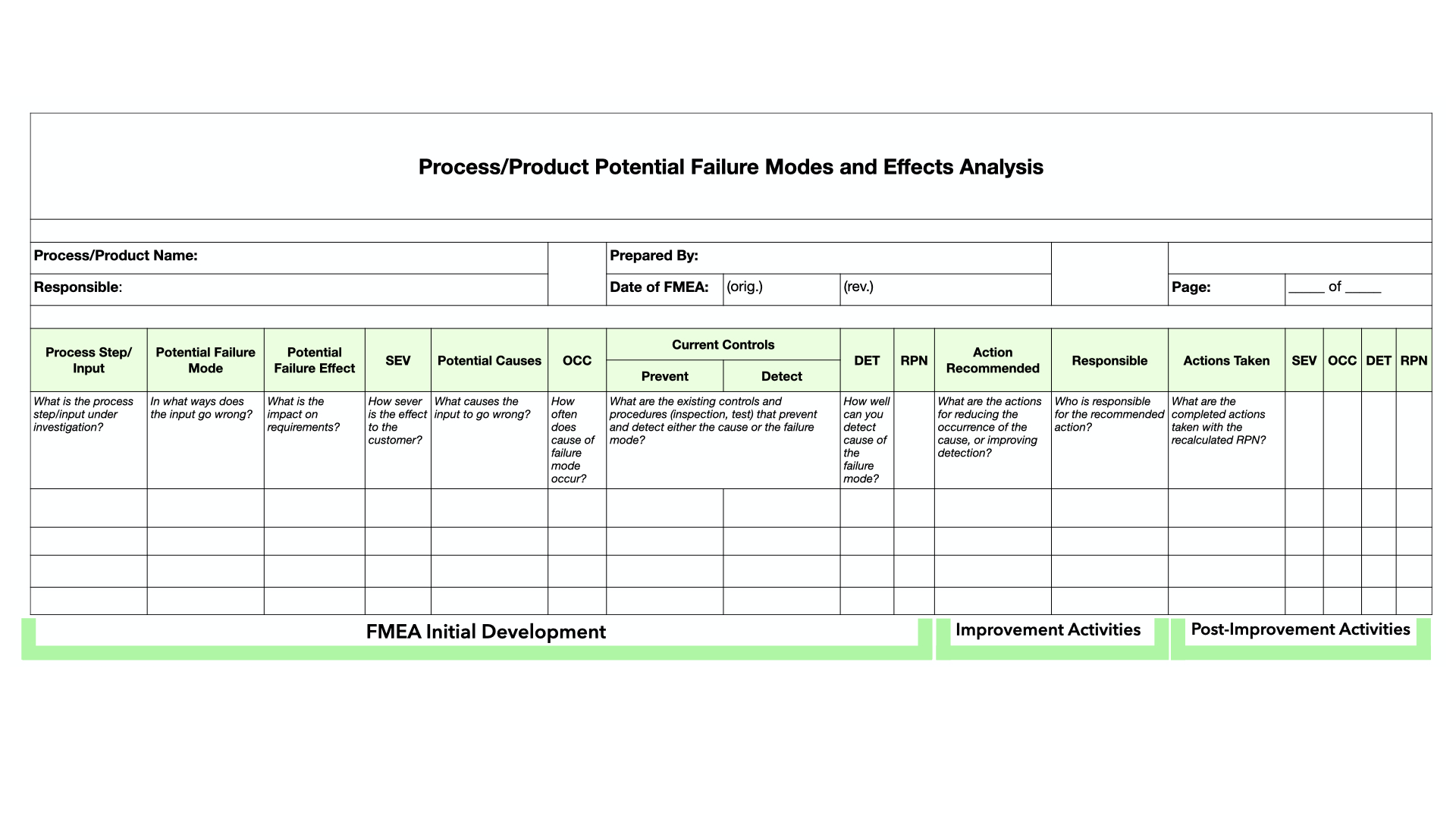

Next, the risk priority number (RPN) for each failure mode needs to be calculated. The RPN is calculated by multiplying the severity, frequency, and detectability scores. This gives a numerical value that helps prioritize which failures should be addressed first. Regulation FMEA documents provide the following templates for the final risk priority assessment.

Figure 3 - RPN Calculation

|

Failure Mode |

Effect |

Severity Rating |

Occurrence Rating |

Detection Rating |

RPN |

|

Incorrect item shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

8 |

4 |

9 |

288 |

|

Incorrect quantity shipped |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue |

7 |

3 |

8 |

168 |

|

Delayed shipment |

Customer dissatisfaction, potential loss of revenue, potential damage to customer relationship |

6 |

5 |

7 |

210 |

|

Damaged product during shipping |

Customer dissatisfaction, potential returns and refunds, potential loss of revenue, potential damage to customer relationship |

9 |

2 |

8 |

144 |

It is important to note that the RPN is not a definitive assessment of failures. It is simply a tool to help prioritize which ones should be addressed first. The FMEA team should use their judgment and experience to determine which failures are the most critical.

Identify and Implement Corrective Actions

Once the RPN is calculated:

- Identify potential corrective actions for high-risk failure modes based on RPN values and other relevant factors.

- Prioritize corrective actions based on feasibility, cost, and potential impact on customer satisfaction and revenue.

- Assign responsibility for implementing corrective actions and establish timelines for completion.

There is an unofficial rule that if a failure mode has a low priority, then corrective actions for it are not carried out or are carried out last.

|

Failure Modes |

Potential Corrective Actions |

Priority |

Responsible Person |

Timeline |

|

Incorrect item shipped |

Implement double-check system for order picking and shipping |

High |

Operations Manager |

4 weeks |

|

Incorrect quantity shipped |

Implement barcode scanning system for order picking and shipping |

High |

IT Manager |

6 weeks |

|

Delayed shipment |

Improve communication between production and shipping teams to identify potential delays earlier |

Medium |

Production Manager and Shipping Manager |

8 weeks |

|

Damaged product during shipping |

Improve packaging materials and methods to reduce damage during shipping |

Medium |

Quality Manager |

10 weeks |

Verify Effectiveness of Corrective Actions

Finally, it is necessary to verify the effectiveness of the corrective measures taken. This step involves:

- Monitoring of the implementation of corrective actions and verify their effectiveness in reducing the risk of high-priority failure modes.

- Establishing a plan for ongoing monitoring and measurement to ensure sustained effectiveness of corrective actions.

- Communicating the results of corrective action verification to relevant stakeholders and update the FMEA analysis as necessary.

|

Corrective Actions |

Verification Plan |

Results |

Updated RPN |

|

Implement double-check system for order picking and shipping |

During a month, do daily reviews of the order selection and shipping records. |

No instances of incorrect item shipped during the audit period |

48 |

|

Implement barcode scanning system for order picking and shipping |

During two months, examine order picking and shipping logs on a weekly basis. |

No instances of incorrect quantity shipped during the audit period |

24 |

|

Improve communication between production and shipping teams to identify potential delays earlier |

During three months, have weekly meetings between the production and shipping teams. |

Number of delayed shipments decreased by 50% during the verification period |

105 |

|

Improve packaging materials and methods to reduce damage during shipping |

During six months, do monthly reviews of consumer comments and returns. |

Number of customer complaints and returns related to damaged products decreased by 80% during the verification period |

29 |

It's essential to remember that FMEA is an ongoing process and should be constantly reviewed and updated as new information becomes available.

Documentation - The FMEA Form

It is not actually the last step of the process, but is performed in parallel with other activities. The FMEA is usually documented in a form that captures all the information gathered during the analysis. The form typically includes information such as the product or process being analyzed, potential failure modes, severity, probability of occurrence, detectability, RPN, and corrective actions taken. It is important to emphasize once again that this form is completed by the entire team during the analysis, during corrective action, and after corrective action, meaning that this process is ongoing, not just done and forgotten.

Figure 4 - FMEA form

FMEA Key Principles

So, the key principles, the FMEA ideology, may now be defined, which include:

- Prevention is better than detection. FMEA aims to identify potential failures before they occur, so that proactive measures can be taken to prevent them from happening in the first place. This approach is more effective and efficient than trying to detect and fix problems after they have occurred.

- Systematic approach. FMEA is a systematic approach that involves a team-based approach to identify potential failure modes, their causes, and their effects on the system. This approach helps ensure that all potential failure modes are identified and analyzed.

- Risk prioritization. FMEA uses a risk-based approach to prioritize potential failures based on their severity, occurrence, and detectability. This helps focus resources on the most critical failure modes and enables effective risk management.

- Continuous improvement. FMEA is an iterative process that is used to continuously improve products, processes, and services. The results of FMEA can be used to inform design improvements, process changes, and other corrective actions to reduce the risk of failures.

- Cross-functional collaboration. FMEA requires collaboration between different functions and departments within an organization to ensure that all potential failure modes are identified and analyzed. This collaboration also helps ensure that corrective actions are implemented effectively.

- Documentation. FMEA results should be documented, including the identified failure modes, their causes and effects, and the recommended corrective actions. This documentation helps ensure that the knowledge gained through the FMEA process is retained and can be used to inform future improvements.

By adhering to these key principles, FMEA assists businesses in identifying and mitigating possible failures, improving product quality, dependability, and lowering expenses related to product recalls, warranty claims, and customer complaints.

FMEA Advantages & Disadvantages

Here are some of its Advantages and Disadvantages:

Advantages:

- Early identification of potential failures. Prior to actual problems developing, FMEA can assist in identifying possible issues throughout the design or production phase. Early detection of possible issues makes it simpler and less expensive to fix them.

- Improved product/process design. FMEA may assist in raising the overall quality of the finished product by spotting possible issues early in the design or production process.

- Improved communication. Different stakeholders must be involved in the risk management process as a result of FMEA, which can enhance their interaction and cooperation.

- Cost-effective. Costs related to the discovery and repair of failures, warranty claims, and recalls can be decreased with the aid of FMEA.

Disadvantages:

- Time-consuming. FMEA is a comprehensive and time-consuming procedure that needs a lot of work and resources to complete.

- Limited scope. The effectiveness of an FMEA depends on the information available at the time it is conducted. It cannot plan for unforeseen or unpredictable threats.

- Over-reliance on subjective assessments. Since FMEA calls for the use of expert opinion and assumptions, the risk assessment may become biased and vulnerable to subjectivity.

- Lack of context. FMEA might not catch every possible failure mode, particularly if the procedure is hurried or the analysts lack the necessary training or expertise.

FMEA Modifications & Extensions

This process is often not used in its raw form in practice. Over the years, the FMEA process has undergone various modifications and extensions. Some common examples are:

- FMECA (Failure Mode, Effects, and Criticality Analysis) is an extension of FMEA that adds a stage for determining the criticality or severity of each failure mode based on a combination of occurrence, detectability, and consequences. Prioritizing the most important failure modes that need urgent attention and mitigation is made easier by the criticality analysis. In industries and safety-critical systems where failure has serious repercussions, FMECA is frequently employed.

- IME(C)A (Intrusion Modes and Effects (and Criticality) Analysis) is a risk assessment approach used to analyze the security and resilience of physical protection systems (PPS) against intrusion attempts by attackers. IMECA is frequently employed in high-security buildings where security breaches might have serious repercussions, such as nuclear power plants, military sites, and government structures.

- Process FMEA is a FMEA variant that concentrates on examining probable failure modes in a manufacturing or production process as opposed to a system or a product. Process FMEA assists in identifying process-related risks that may have an impact on the process' quality, effectiveness, or productivity as well as developing corrective measures to avert or lessen such risks.

- Design FMEA examines probable failure modes at the design stage of a system or product rather than during the manufacturing or production process. Design FMEA assists in identifying design-related risks that may have an impact on the functionality, safety, or dependability of the system or product and in developing design modifications or enhancements to eliminate or reduce such risks.

- Software FMEA is applicable to software development initiatives.It aids in identifying possible failure modes during the phases of software design, coding, testing, and deployment and assists in the development of mitigating tactics to eliminate or minimize such risks. When software is essential to a product's performance and safety, such as in the automotive, aerospace, and medical device sectors, software FMEA is frequently utilized.

Why FMEA is still relevant today

Despite being around for over 70 years, FMEA is still a relevant and valuable tool for many industries. As products and processes become increasingly complex, the need for proactive risk management is becoming increasingly important. FMEA is still relevant today for several reasons:

- Risk management. FMEA helps organizations to identify and mitigate potential risks associated with a product, process, or system. It helps to identify failure modes and their impact on the system, as well as to determine the likelihood of their occurrence

- Quality improvement. FMEA can be used to improve the quality of products, processes, and systems by identifying potential issues and taking proactive steps to prevent them from occurring. This can help to reduce defects, increase customer satisfaction, and improve overall product reliability.

- Regulatory compliance. Many industries, such as healthcare and automotive, require FMEA as part of their regulatory compliance requirements. FMEA helps to ensure that products and processes meet the necessary safety and quality standards.

- Cost savings. By identifying potential issues early on in the development process, FMEA can help organizations to avoid costly mistakes and rework. This can lead to significant cost savings in the long run.

Conclusion

In summary, FMEA is a powerful tool that can help organizations prevent potential failures before they happen, ensuring that they are prepared for anything that could go wrong.

Software Development Hub has extensive experience in creating web applications and mobile applications for healthcare businesses. When working on a project, our team takes into account the business challenges the client faces and offers safe, efficient solutions to automate processes and scale your operations while reducing costs.

Categories

About the author

Share

Need a project estimate?

Drop us a line, and we provide you with a qualified consultation.